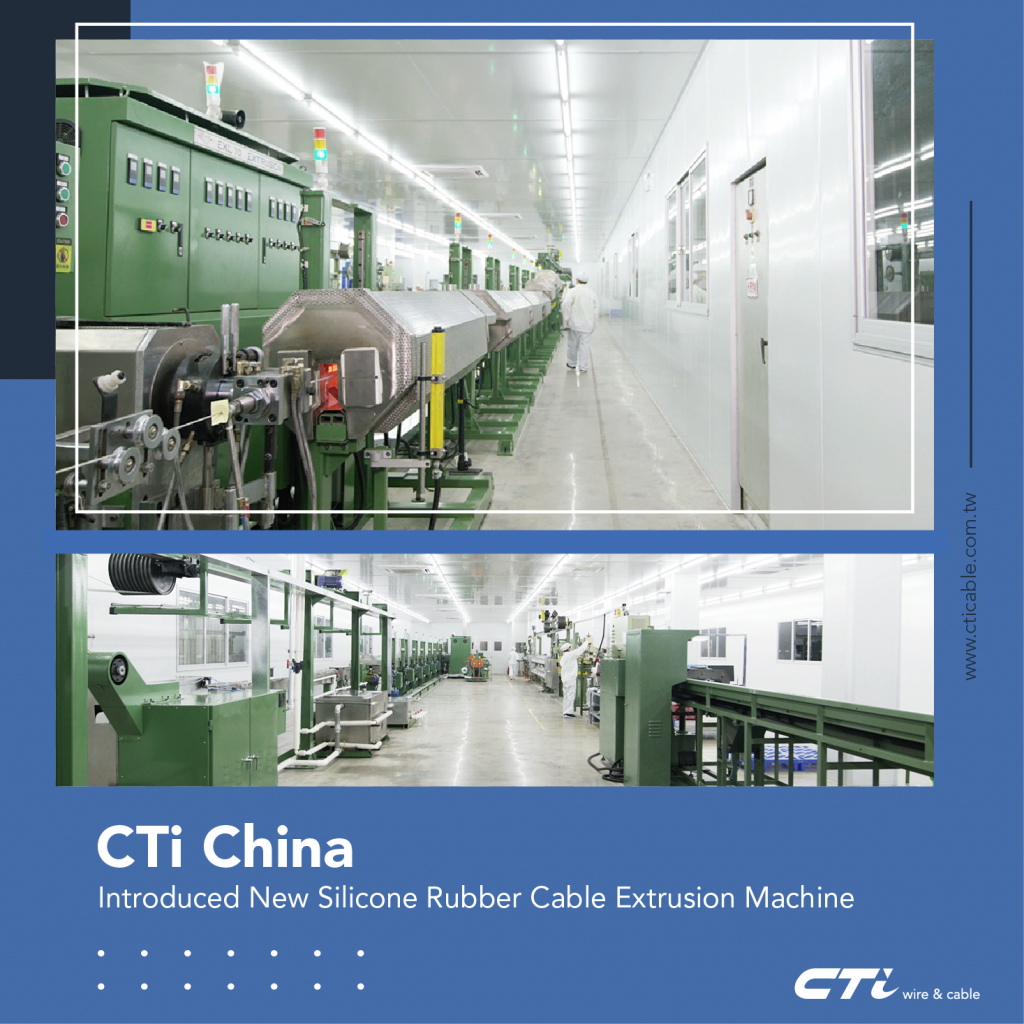

Dongguan Ching Tai Electric Wire & Cable (CTi) introduced new silicone rubber cable extrusion machine.

Silicone rubber is an elastomer (rubber-like material) composed of silicone, which can be found in a wide variety of products including medical devices and implants, electronics, automotive applications, voltage line insulators, and in home repair and hardware.

Silicone rubber is generally non-reactive, stable, and resistant to extreme environments and temperatures while still maintaining its useful properties. Below are the key characteristics of Silicone Rubber:

– High voltage resistant

– Extreme temperature resistant from -40 ~ 150°C

– Acid & alkaline resistant

– Bio-compatibility which is critical for medical applications

– Available for Auto Clave sterilization (up to 134°C) process for medical applications

– Better flexibility and tensile strength

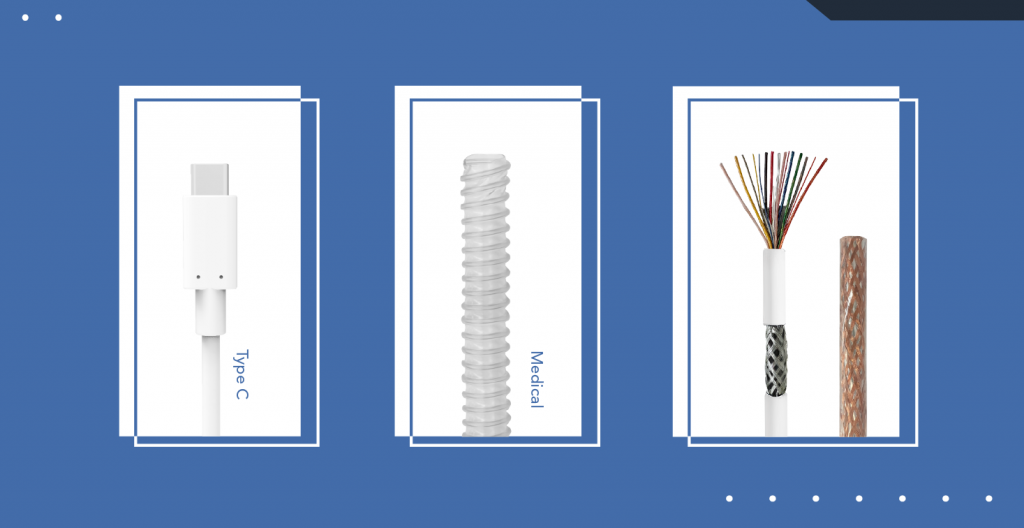

CTi use Silicone Rubber as insulation or jacket material in following product categories:

1. Medical related cable products to meet bio-compatibility & sterilization requirements.

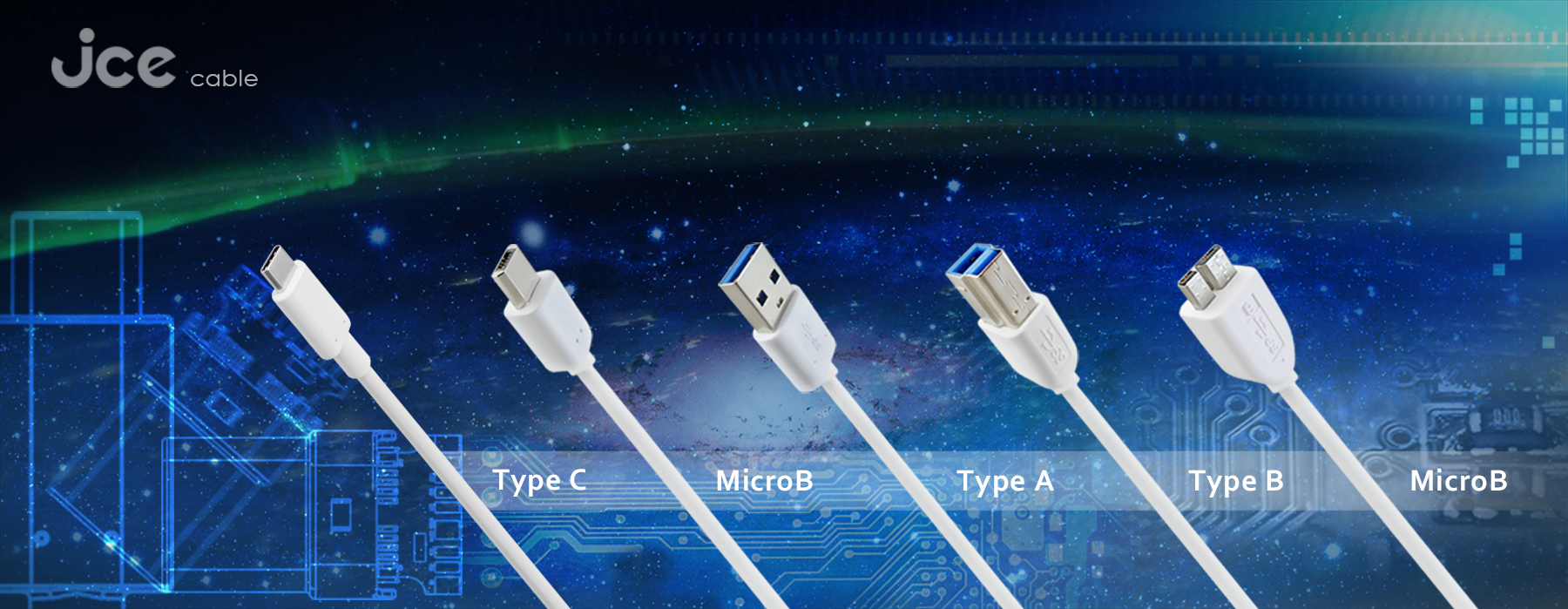

2. Consumer products such as USB-C and HDMI for premium touch & feel.

3. Power or heat related cable products which required extreme temperature or high voltage resistant.

CTi Group is a professional cable OEM/ODM solution provider established in Taiwan for the past 60 years. CTi Group has been dedicated to the integrity of high-frequency and high-speed cable industry for many years which provides customers with product design, development, and production solution by integrating outstanding tooling design, industrial automation, and procedure capability. CTi Group’s main products include HDMI, USB, DP, networking cable, VR HD cable, automotive cable, industrial and medical cable, etc.